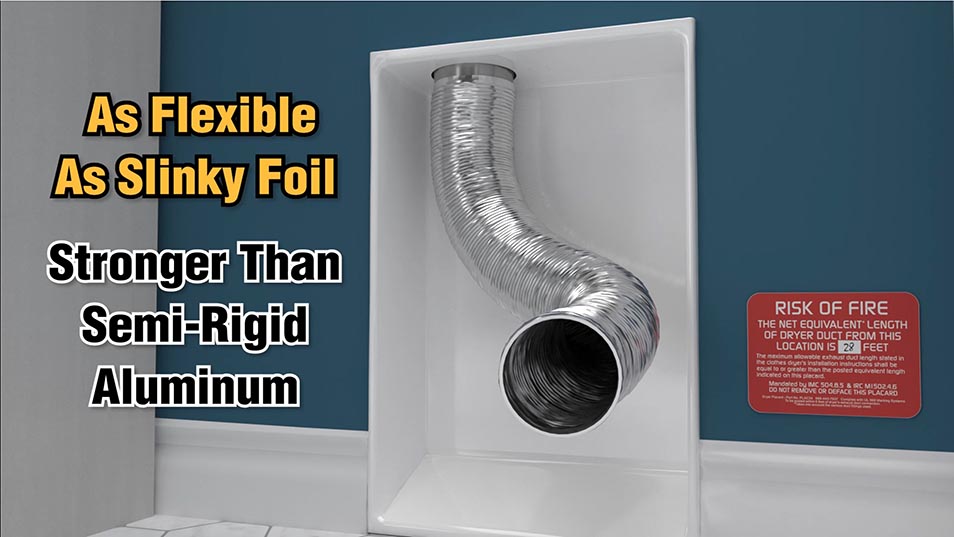

Dryer Transition Hose Connection Comparison

DryerFlex® has all of the good features of foil and semi-rigid without any of the shortcomings.

| Characteristic | "Slinky" Foil | Semi-rigid | DryerFlex |

|---|---|---|---|

| Rigidity |  |

|

|

| Workability |  |

|

|

| Compression |

9:1

|

3:1

|

8:1

|

| Crush Resistance | NO | NO | YES |

| Dryers get pushed back and can naturally vibrate against the wall over time. Both foil and semi-rigid collapse quickly which can create an immediate fire danger. |

|||

| Flame Spread Resistance | NO | SOME | YES |

| DryerFlex has been UL tested and stands up to 482° without catching fire. Be aware that some hose is made with a Mylar coating which is highly flammable and will exacerbate a fire. Even some readily available semi-rigid does not perform as well as DryerFlex. | |||

| Inside Diameter | 3.25" | 4.0" | 4.0" |

| Airflow restriction wastes energy by increasing dryer times, and it increases lint build up and the possibility of a dryer fire. DryerFlex has a smooth interior similar to semi-rigid which allows the dryer to perform at peak efficiency. | |||

| UL 2158A | NO | SOME | YES |

| Code and manufacturer required UL2158A listing. | |||

Comparison Summary: Foil

Like DryerFlex, foil transition hose is pliable and easy to work with. However, building code prohibits the use of foil in an attempt to reduce the number of fires caused by dryer exhaust problems. Foil duct has a narrower, rough interior that restricts airflow and a coating that is flammable.

Comparison Summary: Semi-rigid

Semi-rigid is accepted under standard building code because it maintains its 4" diameter and has a smooth interior. It is harder to work with, crushes easily and is difficult to twist. DryerFlex is also code approved with a UL 2158A listing, but it is very workable making it easier to connect the dryer.

Printable Product Comparison PDFThe DryerFlex Advantage

DryerFlex outperforms other exhaust hose because of its unique design: all metal construction using five layers of 25 micron aluminum ribbon wound over galvanized, zinc coated wire.

Strength

This approach to building a better transition duct makes DryerFlex tough enough to protect against punctures or crushing, helping prevent efficiency loss and fire dangers. In the event of a dryer fire, this design can work to hinder fire expansion into the wall with torch tests up to 482 degrees showing zero flame spread or smoke development.

Flexibility

Some of the same features that make DryerFlex tough, including the wrap of multiple ribbon layers over a spiral wire, also makes DryerFlex easy to manipulate into the right bend for every dryer connection.